Product description: Motion Control for Stepper Motors

|

Stepper Controller for 4 individual

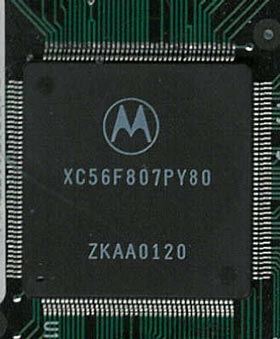

Steppermotors realized with 2 Digital Signal Processors from Motorola

5680x

Sin-Cosinus Microstepping (64Microsteps per Steps) Half-step-frequency from 5Hz to 64'000Hz Motorcurrent-Range from 120mA up to 10.0A with the same PCB!! |

|

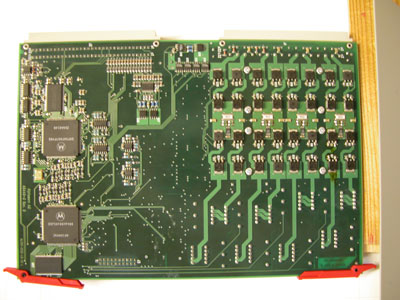

Backside of PCB with Motoramplifier on the right side and the XILINX FPGA for Dual Ported Ram simulation and some other misc. application |

BNB Stepper Motor- Control - Unit realized with Motorola DSP 56807 (Digital Signal Processor)

Download complete Documentation and product description

| Software Features: | 0. Twin Stepper Controller Card (1 Processor Unit for 2

Axis) 1. Adjustable maximum Half step- Frequency from 5Hz to 64'000Hz with steps of 1Hz 2. Realization of 64 Microstepps between a full step. The Microstepping runs thought the complete frequency range. There is no switch from Micro- Stepping to Half-Step to Full step or vice versa. 3.Sinus - Cosines, field oriented Current Controlled by the DSP with a clock rate of 30Khz. That means that the actual current is measured, converted from analog to digital, compared with the set-point using a PI- calculation and the new PWM Value is the new control value 4. Adjustable Chopperfrequncy from 15Khz to 240Khz, synchronized between the different axis 5. S-curve and trapezoid acceleration 6. absolute, relative, infinite movement, Speed controlled movement, Position Controlled movement with a sampling rate of 5Khz 7. Motor-Identification. Just connect a new motor, restart the controller and the

controller detects which motor is hocked up to the controller. This automizes the set of:

the following parameters 8. We implemented various interfaces to control the Motor-Control-Unit: 9. There a various General Purpose Pins available which can be configured as Limit- Switches, Reference Sensors, Count- Sensors with adjustable Glitch-Filters. 10. Automatic Adjustment of Analog Signals, like the offset for the current measuring circuit 11. Encoder Feedback for Closed- Loop Positioning (Stepper Application will become a Server- Application)

|

| Hardware Features: | 1. One DSP (Digital Signal Processor) from Motorola can

control 2 Stepper Motors 2. The Software is developed for a hardware with the Current Range from 120mA to 10A. That means we can control Motors in the range of 200mA Run Current, with a hold current of 100mA. The Current resolution is 14mA, on one side on the other up to 10A with the same amplifier. 3. Additional (to the software) Over current Limitation and safety circuit 4. Current Measuring realized with current - converter, so there are no precise high power resistor required, which produces heat.

|

| used Motorola DSP 56807 (Digital Signal Processor) |  |

| Just a example of an average Stepper- Motor |  |

| Software Development Environment | All software - Development has been done with Metrowerks

CodeWarrier Release 5.x. The time critical Task like the Current - Controller are

implemented in assembly. (They use about 50% of the processor resources), all the other

functions in Standard ANSI C.

|

© Copyright 2001 Brauchli Netsolution Berg All rights reserved. info@brauchli-netsolution.ch